Check out our latest products

The modular DC link capacitor boosts vehicle powertrain efficiency. It is designed to meet diverse needs with customizable options and standards compliance.

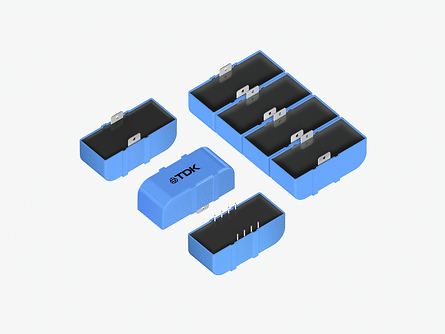

TDK Corporation has launched the xEVCap, a modular DC link capacitor designed for powertrain inverters in various vehicles and machinery tools. Traditional capacitor designs are custom-made, time-consuming and cost-effective only in large production runs. Moreover, changes in customer requirements during a project can further delay development. The main applications for the DC link include main traction inverters used in passenger cars, commercial vehicles, off-highway vehicles, and machinery tools.

The capacitor offers a modular design that allows inverter designers to adapt to different capacitance and current needs even in smaller production quantities, thus saving time and reducing costs. The design uses standardized modules to decrease the variety of stocked components and allows for easy parallel connection to achieve desired specifications. It meets automotive standards AEC-Q200 rev. E and IEC TS 63337:2024.

The capacitor can be connected via lead wires or flat terminals in two styles. It comes in various sizes and voltage ratings, ranging from 500 V to 920 V and capacitances between 60 µF to 270 µF.

Some of the key features of the xEVCap include:

- Scalable and modular for different power levels and densities

- Compatible with wide-bandgap power semiconductors (SiC, GaN)

- Good self-healing properties

- Low ESR and low ESL

- Compliant to IEC TS 63337:2024 (all versions)

- Compliant to AEC-Q200 rev. E (lead wire versions)

The capacitor supports temporary voltage surges—such as 850-V types handling 890 V for up to 100 hours at +105 °C—and operates within a temperature range of -40 °C to +105 °C, with surge voltages up to 1200 V. The rated currents vary from 35 A to 60 A, with low equivalent series inductance.

For more information, click here.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)