Check out our latest products

An IC transforming PCBs into high-precision angle encoders, offering cost-effective and efficient angular position measurements.

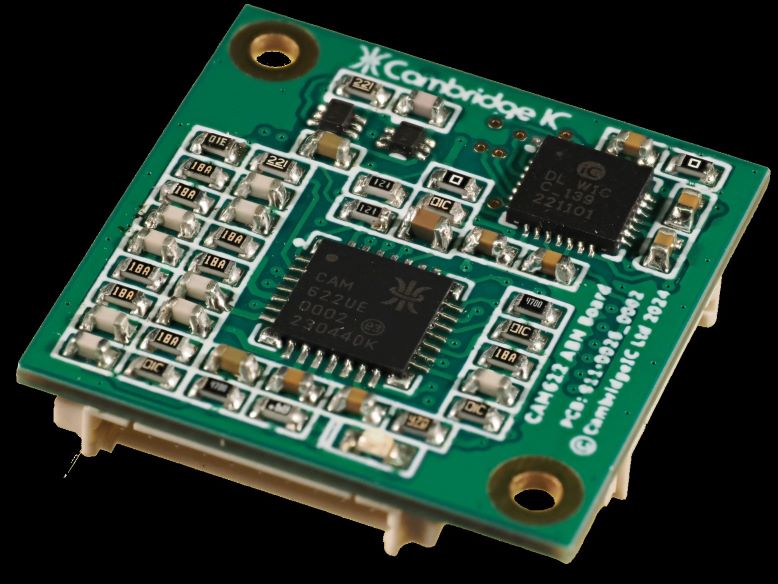

A groundbreaking innovation in angular position measurement, the ‘CAM622’ resonant inductive encoder IC, has been introduced by CambridgeIC, UK. This technology leverages printed circuit boards (PCBs) to create precise, contactless angle encoders, offering a balance of speed, accuracy, and cost-efficiency.

Designed to connect with sensors, the IC measures the angle of a rotating target and delivers standard quadrature encoder ABN outputs. Its unique feature lies in using PCB coil patterns as sensors, enabling compact and reliable designs. These PCB-based sensors are easy to produce and eliminate the need for calibration, making them a practical choice for industrial applications. Manufacturers in robotics, automation, and machinery stand to benefit significantly from this advancement, as it streamlines the integration of precise angle measurements into their systems.

The IC’s innovation extends to its ability to operate with resonant targets also constructed from PCB coils. These targets, enhanced by surface-mounted capacitors, form resonant circuits that outperform traditional inductive sensing methods. This supports various sensor and target sizes, such as the 25mm B3 Sensor and the larger 50mm B5 model, which accommodates through shafts.

Type B Sensors and Targets, a new design introduced with this technology, maintain high accuracy despite installation misalignments. For instance, the 25mm B3 Sensor achieves better than ±0.14° linearity error with radial and tilt misalignments of up to ±0.3mm and ±0.3°, respectively. This flexibility in mounting allows for cost-effective integration using conventional methods like screws.

It offers exceptional angular resolution, generating quadrature ABN outputs at up to 16 bits. It simplifies mechanical assemblies by replacing optical encoders, eliminating components like bearings and seals. Programmable ABN outputs make it versatile, accommodating diverse applications with software adjustments alone.

To meet high-performance demands, the IC processes up to 33,000 measurements per second, significantly surpassing its predecessor. It also handles extreme rotational speeds, tested up to 66,000 rpm with the 25mm B3 Sensor, ensuring precision even under dynamic conditions.

An accompanying CAM622 ABN board is available, providing a comprehensive solution that integrates seamlessly with Type B sensors, delivering efficient and precise angular measurement.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)