Check out our latest products

A unique eco-friendly method redefines graphene’s potential, showing its use in advanced electronics, renewable energy, and flexible devices.

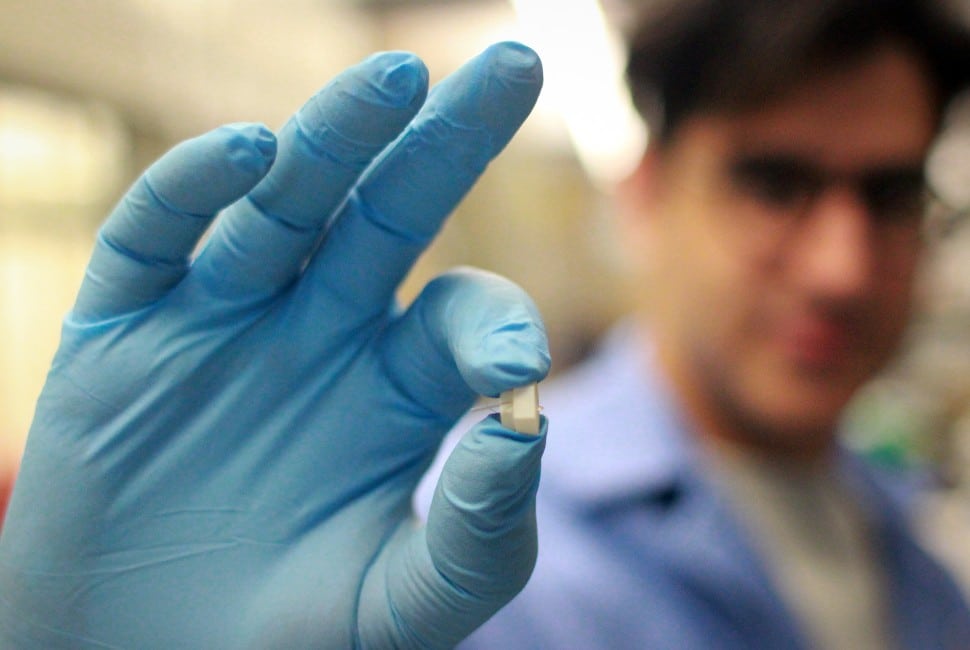

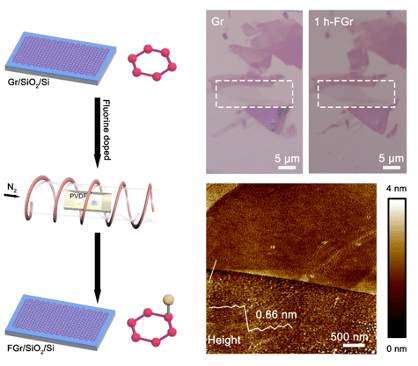

Researchers at Tohoku University, in collaboration with global experts, have pioneered an eco-friendly fluorination method to overcome graphene’s zero-bandgap limitation. This advancement modifies graphene for use in optoelectronic and energy devices while maintaining its superior electrical properties.

Graphene’s continuous electrical conductivity, stemming from its lack of a bandgap, has long limited its adaptability in electronics that demand controlled electricity flow. A bandgap acts as a “gate,” enabling devices to switch electricity on and off, as seen in smartphones and computers. Traditional approaches added fluorine atoms to graphene to introduce this functionality, but they relied on toxic chemicals, rendering them unsuitable for large-scale use.

“We developed an environmentally friendly approach, one where we utilised fluoropolymers under controlled conditions to achieve selective fluorination,” explained Dr Yaping Qi, assistant professor, Tohoku University. This method not only enhances photoluminescence but also preserves carrier mobility and enables tuneable transport properties, making it particularly promising for industries like LED manufacturing, renewable energy, and flexible electronics.

Employing advanced techniques such as photoluminescence mapping and Raman spectroscopy, the team demonstrated significant improvements in graphene’s optical properties. The enhanced light emission and structural integrity position fluorinated graphene as a viable candidate for devices like sensors, wearables, and energy storage systems.

Further exploration focused on integrating fluorinated graphene into Van der Waals (VdW) heterostructures, where layered 2D materials achieve multifunctionality. These structures are critical for applications in artificial intelligence, memory storage, and smart electronics. “The integration of fluorinated graphene into VdW heterostructures opens up exciting possibilities, especially for flexible electronics and systems that can perform multiple tasks at once,” noted Dr Xichan Gao, assistant professor, AIMR.

Dr Qi emphasised the broader impact, stating, “Combining fluorination with strain engineering opens new possibilities for scalable, high-performance 2D materials.” This breakthrough aligns with the growing demand for sustainable material processing in cutting-edge technologies, offering scalable solutions for researchers, manufacturers, and innovators alike.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)