Check out our latest products

The design helps extend battery life, optimize power management, and ensure reliable operation of fault indicator systems using energy harvested from solar cells.

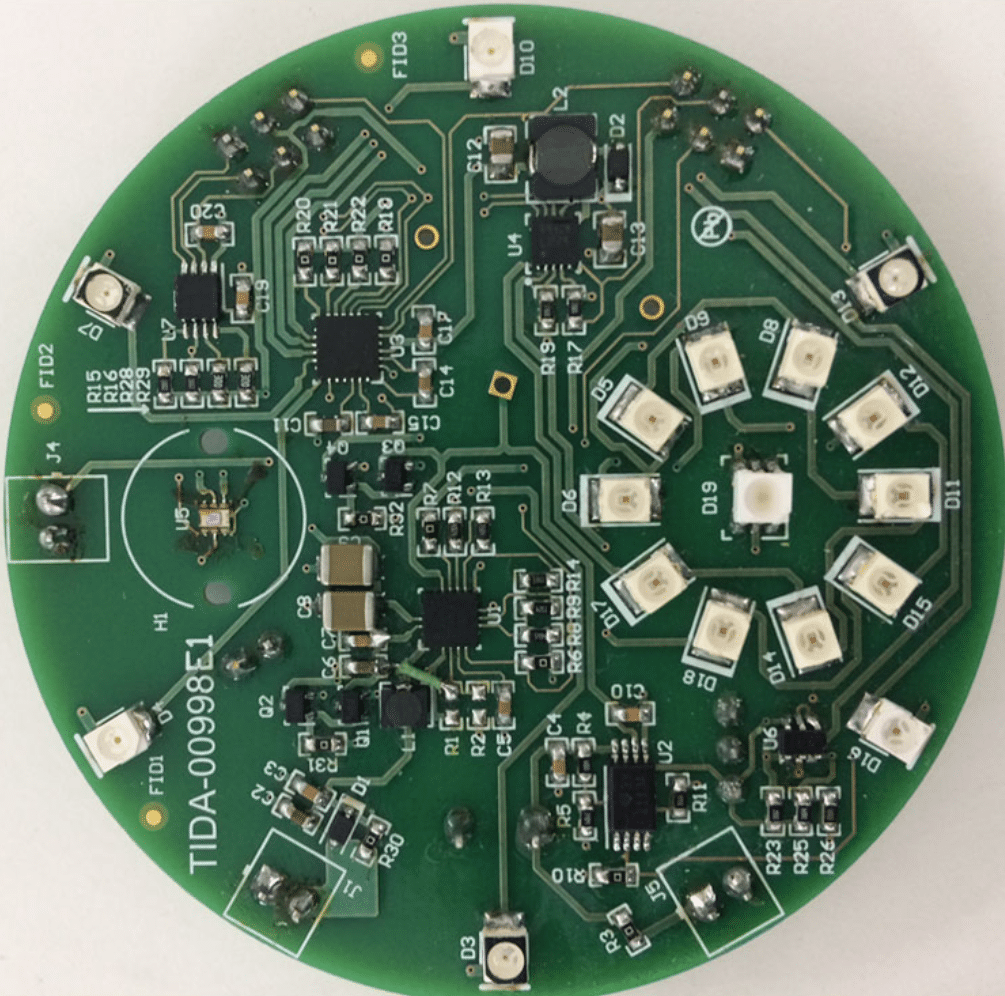

Design engineers working on overhead fault indicators (OHFIs) can leverage the TIDA-00998 reference design from Texas Instruments (TI) to address key challenges in energy management. This design provides multiple architectures to extend the primary battery life by incorporating a secondary battery or supercapacitor, with energy harvested from a current transformer (CT) or solar cells. By optimizing power management with efficient LED drivers, engineers can control the LED intensity to ensure uniform 360° visibility and extend the operational lifespan of fault indicators during outages.

The reference design can be used by design engineers, electrical engineers, product developers, field engineers, maintenance teams, utility companies, and system integrators working on overhead fault indicators (OHFIs) or related systems in the energy and utility sectors.

The reference design supports fault indicators used to monitor power cables and detect faults on transmission lines. These indicators help reduce operational costs and service interruptions by identifying faulty cable sections and enhancing safety by minimizing the need for hazardous fault-chasing procedures. TIDA-00998 enables the design of fault indicators that reliably signal fault currents and adapt to various electrical network characteristics. Engineers can ensure these indicators reset quickly after faults by utilizing load current or voltage. Additionally, the design includes features to prevent false tripping from inrush currents caused by reclosing protective devices.

The reference design focuses on extending the life of the OHFI with a low ampere-hour (Ah) battery, a critical challenge in fault indicator systems. With the TIDA-00998, engineers can design systems that optimize flashing hours, allowing the OHFI to signal a fault for up to 24 hours, depending on the fault type. The energy harvesting aspect of the design can capture energy from both low current inputs (via CT) and solar energy, even when input voltages are as low as 80 mV, thanks to the bq25505’s boost controller and maximum power point tracking (MPPT) functionality.

Engineers can choose rechargeable batteries, supercapacitors, or conventional capacitors to store the harvested energy based on the required operating voltage range. The reference design allows integration of either a CT-based energy harvesting subsystem or solar cells, providing flexibility in how energy is collected and stored, ensuring reliable operation and easy scalability for various fault indicator applications.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)