Check out our latest products

The solid electrolyte membrane is made using a dry process. It is thin, improves energy density, reduces battery size, and supports all-solid-state batteries.

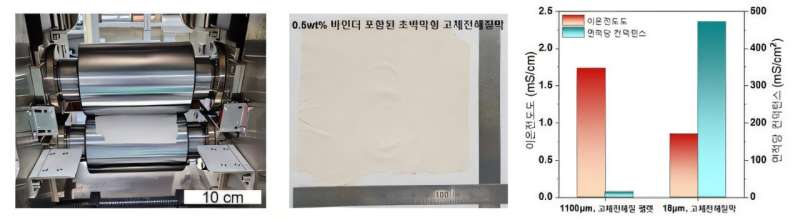

The Electronics and Telecommunications Research Institute (ETRI) created a solid electrolyte separation membrane using a binder material that fibrillates when subjected to mechanical shear force. This was achieved through a solvent-free mixing process with solid electrolyte powder. The resulting membrane is thin and durable.

Typically, solid-state battery membranes are made several hundred micrometers (µm) to 1 millimeter (mm) thick to enhance durability when using solid electrolytes. However, this thickness reduces energy density compared to polymer separation membranes.

To address this, the research team used a binder material that fibrillates under mechanical shear, enabling the production of a solid electrolyte membrane just 18µm thick—comparable to lithium-ion battery membranes. This was achieved through a dry manufacturing process.

As a result, they reduced cell volume while increasing energy density and performance. The new membrane improves energy density by up to 10 times compared to a 1 mm thick solid electrolyte membrane.

This research enables the development of all-solid-state secondary batteries with higher energy density by improving ion transfer between charge and discharge. It also reduces cell volume and weight using a solid electrolyte membrane as thin as polymer separation membranes.

The study identified a link between the molecular weight of the binder material and the strength of its entanglement, providing a process guideline for optimizing solid electrolyte membranes. This allows for cost-effective production with precise binder amounts.

ETRI researchers optimized a mechanical shear process to maximize the entanglement of the fibrous binder, a key factor in the dry process, enabling the production of solid electrolyte membranes.

By analyzing the structure of the polymeric binder, the researchers quantified the relationship between its molecular weight and the degree of entanglement during fibrillation. By fine-tuning process temperature and shearing time, they achieved up to 98% polymer binder fibrillation, forming an entangled binder network.

While this study focused on thinning solid-state electrolytes, ETRI researchers plan to further enhance ion conductivity and improve interface stability with electrodes. They also developed a pouch-type cell using the solid electrolyte membrane and reported charge/discharge results, indicating potential for commercialization.

Reference: Seokyoon Yoon et al, Regulating Entanglement Networks of Fibrillatable Binders for Sub‐20‐µm Thick, Robust, Dry‐Processed Solid Electrolyte Membranes in All‐Solid‐State Batteries, Small (2024). DOI: 10.1002/smll.202407882

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)