Check out our latest products

Specifically designed to enhance the “Reverse Hybrid” assembly process for next-gen electronics, offering superior reliability and higher yield rates.

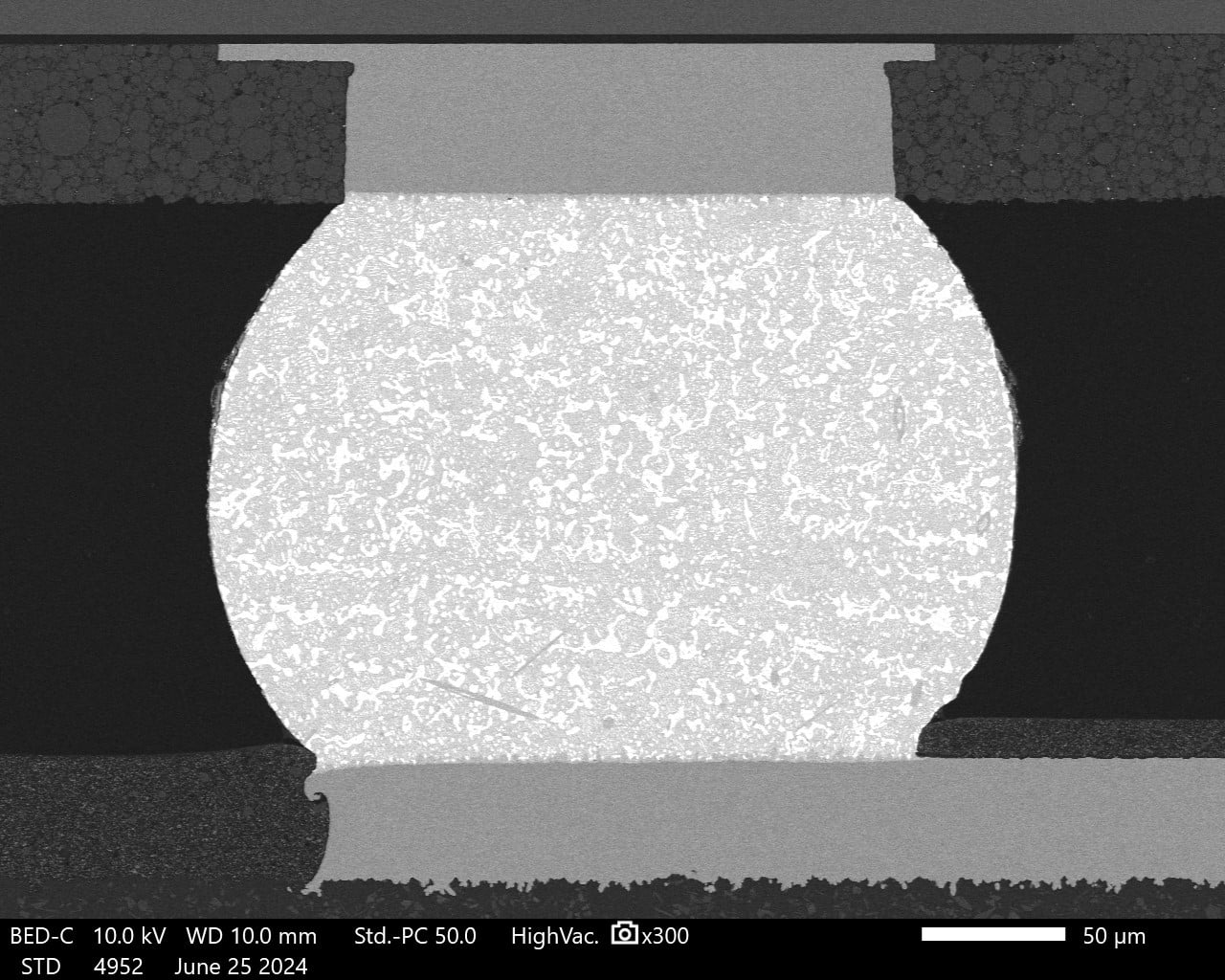

SHENMAO America, Inc. unveils its PF606-P lead-free solder paste, tailored for the advanced “Reverse Hybrid” board assembly process. This innovative technique is gaining traction in the electronics industry due to its ability to improve product reliability and increase manufacturing yields for cutting-edge devices.

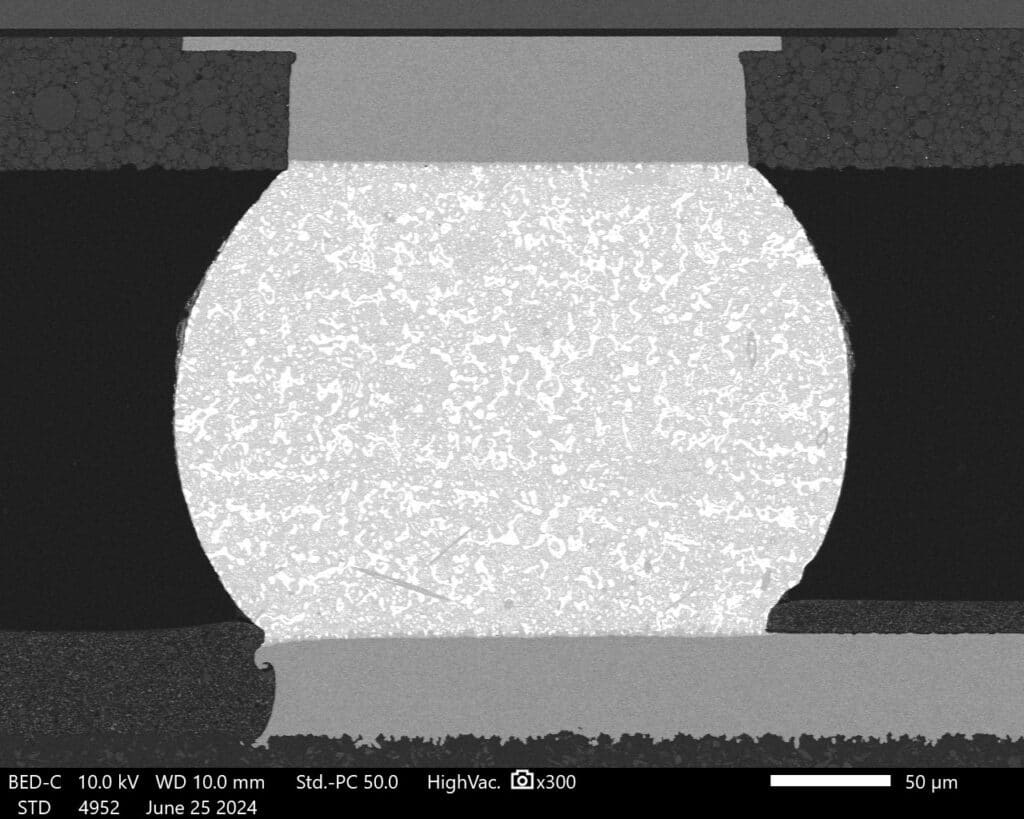

The “Reverse Hybrid” assembly process pairs SAC (Sn-Ag-Cu) solder paste with BGA components that feature low-temperature solder (LTS) balls. A traditional SAC reflow profile is used for soldering, which results in a homogeneous SAC-LTS solder joint. This process contrasts with the conventional “LTS Hybrid” approach, which uses LTS paste and SAC balls but often results in lower thermal reliability.

By incorporating this method, manufacturers can achieve:

- Higher yield rates and enhanced long-term reliability

- Seamless compatibility with existing SAC SMT materials and reflow processes

- Improved thermal cycling (TC) and drop test performance

- Consistent solder joint quality and superior mechanical strength

This approach is particularly beneficial for next-generation advanced packages, such as CPUs, where LTS solder balls lower the ball-attach process temperature. Despite the use of LTS components, manufacturers can still maintain standard SAC reflow conditions, simplifying integration and minimizing process complexity.

It is ideal for this application, providing excellent printability, solderability, and minimal voiding. Its specially formulated flux ensures tight void control and reduces short defects caused by void expansion during soldering. Leading manufacturers are already adopting the solder paste as they explore Reverse Hybrid solutions to meet the demands of modern, high-performance electronics.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)