Check out our latest products

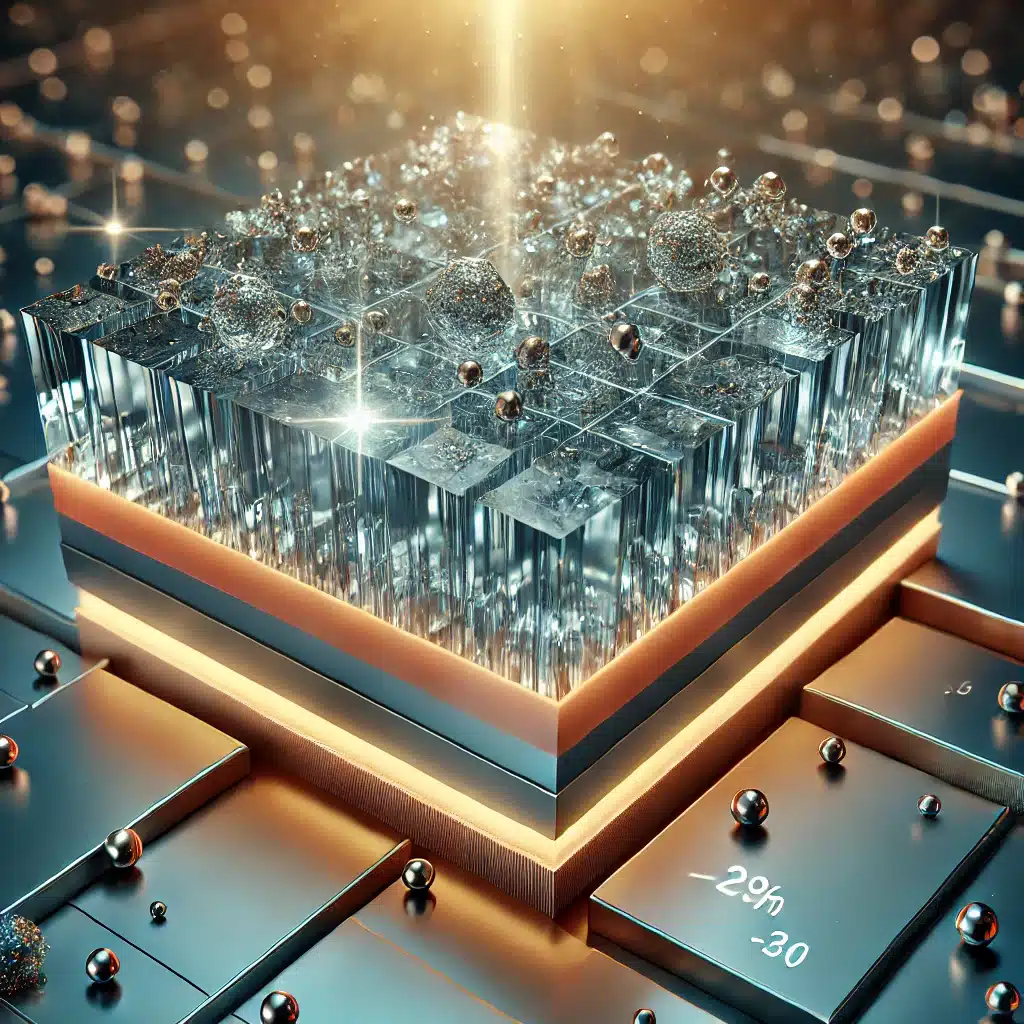

Researchers at North Carolina State University, US have developed a technique to engineer layered hybrid perovskites (LHPs) at the atomic level, enhancing their efficiency in converting electrical charge into light for use in LEDs and lasers.

The research group of North Carolina State University have developed hybrid Perovskites, defined by their unique crystalline structure and possessing exceptional optical and electronic properties. LHPs consist of ultra-thin sheets of perovskite material separated by organic “spacer” layers. These materials can be formed into thin films comprising multiple perovskite sheets and spacer layers, making them highly effective in converting electrical charge to light, which is crucial for future technologies in LEDs, lasers, and photonic integrated circuits. The primary target audience for these advancements includes researchers, engineers, and manufacturers in the fields of electronics, photonics, and renewable energy, who are seeking innovative solutions for energy-efficient devices.

Despite their potential, researchers have struggled to understand how to manipulate these materials to optimize their performance. A key aspect of their study involves quantum wells, which are thin layers of semiconductor material interspersed between spacer layers. “We knew quantum wells were forming in LHPs—they’re the layers,” explained Aram Amassian, materials science and engineering professor & corresponding author, North Carolina State University.

The research team discovered that the size distribution of these quantum wells significantly affects energy flow at the molecular level. “A quantum well that is two atoms thick has higher energy than a quantum well that is five atoms thick,” noted Kenan Gundogdu, a co-author & professor of physics, North Carolina State University. The researchers aimed to create an efficient energy flow by ensuring a gradual size transition between quantum wells.

Through extensive experiments, they identified nanoplatelets as a critical factor in addressing discrepancies between different measurement techniques. “Nanoplatelets are individual sheets of the perovskite material that form on the surface of the solution we use to create LHPs,” Prof. Amassian remarked. These nanoplatelets serve as templates, dictating the thickness of the quantum wells below them.

The findings clarify the difference in results from X-ray diffraction and optical spectroscopy. While diffraction focuses on stacked layers, spectroscopy detects isolated sheets. The researchers can now control nanoplatelet growth, allowing for precise tuning of quantum well size and distribution, leading to enhanced energy efficiency for laser and LED applications.

The team also investigated the potential of nanoplatelets to improve other perovskite materials, particularly those used in solar cells. “We found that the nanoplatelets play a similar role in other perovskite materials and can be used to engineer those materials to enhance the desired structure,” stated Milad Abolhasani, co-author and ALCOA Professor of Chemical and Biomolecular Engineering, North Carolina State University. This approach promises to improve photovoltaic performance and stability in future energy technologies.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)