Check out our latest products

A low-temperature method to create safer, high-performance solid-state batteries, potentially transforming energy storage in everything from smartphones to electric vehicles.

In a promising leap for next-gen energy storage, researchers at Penn State are advancing solid-state battery technology that could replace the traditional—and often hazardous—lithium-ion batteries found in phones, laptops, and electric vehicles.

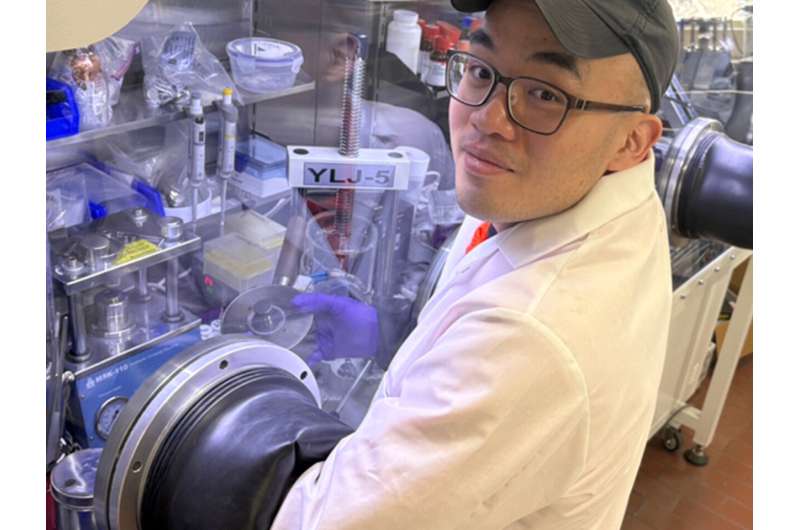

The team, led by Hongtao Sun, assistant professor of industrial and manufacturing engineering, is focusing on solid-state electrolytes (SSEs), which replace the flammable liquid electrolytes in conventional batteries. SSEs offer superior thermal stability and safety, but historically, they’ve been difficult to produce due to high processing temperatures and poor conductivity.

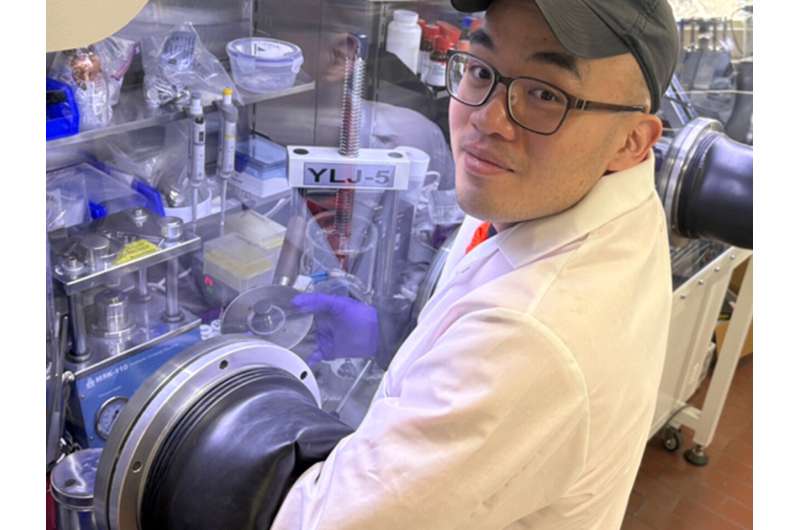

To solve this, Sun’s team employed a technique known as cold sintering—a low-temperature process that compresses ceramic powders into dense forms using pressure and a small amount of solvent. This method allowed the researchers to create a new ceramic-polymer composite SSE called LATP-PILG, combining the high conductivity of a poly-ionic liquid gel (PILG) with the stability of ceramic LATP. “Traditional sintering requires temperatures near 1,000°C,” Sun explained, “but cold sintering lets us keep it to around 150°C. That’s low enough to preserve the polymer components while densifying the ceramic.”

A major innovation lies in how the team tackled ion transport issues. Normally, grain boundaries in ceramic materials impede conductivity. But by integrating PILG into the grain boundaries, they created engineered pathways that enhance ionic movement and reduce energy loss. The resulting composite SSE not only boasts high room-temperature conductivity, but also supports a wider voltage window (0 to 5.5 volts), compared to the 0 to 4 volts typical of liquid electrolytes. This means the batteries can use high-voltage cathodes and deliver more energy.

Looking ahead, Sun envisions broad applications for cold sintering beyond batteries—into semiconductor manufacturing and general ceramics processing. “Our next step is developing a sustainable, scalable production model,” he said. “That’s where the future of this technology lies.”

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)