Check out our latest products

By leveraging DNA’s self-assembling capabilities, Columbia’s research marks a step toward a future where electronics build themselves—one molecule at a time.

Researchers at Columbia Engineering have achieved a feat—using DNA to create 3D, electronically operational devices with nanoscale precision. This innovation could significantly enhance computing power by shifting from traditional 2D microchip architectures to complex 3D structures.

“Going from 2D to 3D can dramatically increase the density and computing power of electronics,” said Oleg Gang, professor of chemical engineering at Columbia Engineering and leader of Brookhaven National Laboratory’s Soft and Bio Nanomaterials Group.

– Advertisement –

The new technique may also pave the way for AI systems that mimic the brain’s natural 3D architecture. “These structures could be far more effective at running AI than conventional 2D architectures,” Gang noted.

From Etching to Self-Assembly

Traditional electronics manufacturing follows a top-down approach, where material is etched away to create circuits. However, this method struggles with precision and cost-effectiveness when constructing 3D devices.

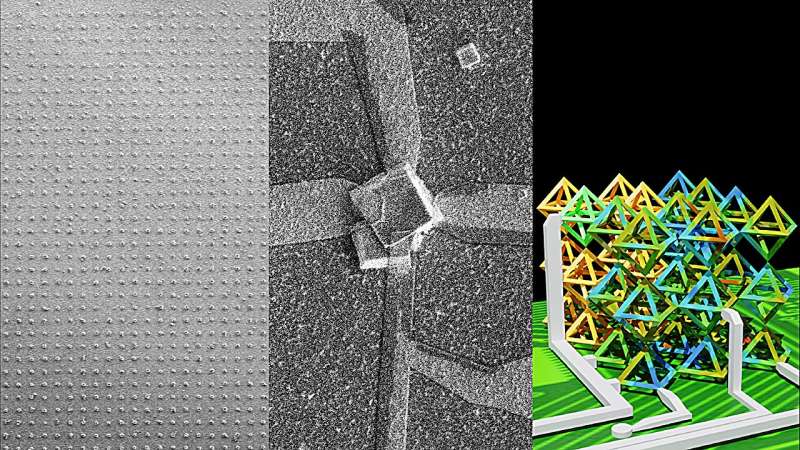

Instead, Columbia researchers developed a bottom-up approach using DNA origami—where DNA strands self-fold into desired shapes. These shapes then assemble into large-scale 3D frameworks, ensuring nanoscale accuracy.

DNA’s natural pairing rules—A with T, and C with G—allow scientists to program specific folding patterns. By leveraging these properties, researchers can construct precise nanostructures suited for electronic applications.Led by Aaron Michelson, a staff scientist at Brookhaven National Laboratory, the team deposited gold squares onto a surface, attaching short DNA strands as anchors. These anchors guided the self-assembly of octahedral DNA frames into 3D structures at designated locations.

Collaborating with the University of Minnesota, the researchers then coated the DNA structures with silicon oxide and tin oxide—key semiconductor materials—and integrated electrodes. The result: functional light sensors that generate electrical responses when exposed to light. This advancement proves that DNA-assembled 3D structures can be integrated into microchips, potentially transforming semiconductor manufacturing.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)