Check out our latest products

Navigating modern PCB design can feel overwhelming. From CAD tools to supplier selection, Part 1 of this series offers actionable insights to simplify your journey.

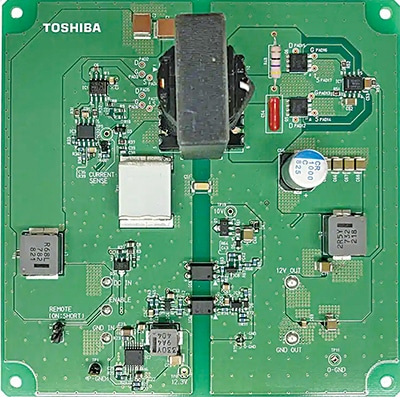

The printed circuit board (PCB) industry continues to expand and evolve, with designers now facing heightened challenges post-Covid, including component end-of-life issues and supply chain uncertainties. The demand for flawless, first-attempt designs has never been higher.

This series is designed to guide PCB engineers in creating innovative and manufacturable designs while navigating the complexities of modern product development. For those new to PCB design or with limited experience, understanding the principles of ‘Designing for Reality’ is critical. This approach emphasises robust methodologies that ensure reliability, manufacturability, and compliance with diverse design requirements.

Success depends on meticulous attention to detail. PCB design is shaped by unwritten rules, best practices, and varying manufacturer-specific requirements. Visiting manufacturing facilities is a valuable step towards grasping the nuances of board production, which can differ significantly depending on the classification and design specifications.

By partnering with reliable manufacturers and developing a deep understanding of production fundamentals, designers can overcome challenges and consistently achieve functional, cost-effective designs—even as projects grow more complex.

A glimpse ahead

This series will explore essential strategies for PCB designers, beginning with selecting the right CAD tools, qualifying suppliers for seamless production, and mastering component placement. Subsequent parts will delve into advanced topics, such as plating processes, managing manufacturing variations, leveraging computer-aided manufacturing (CAM), and integrating best practices for enhanced reliability and manufacturability.

Selecting the right CAD tool

The market offers a broad range of CAD tools for designing PCBs. Choosing the right one is crucial for ‘designing for reality.’ While seasoned designers prefer established tools, beginners often gravitate towards free or simpler electronic design automation (EDA) software. Avoid letting managerial preferences dictate the decision. Instead, prioritise software that aligns with your design-to-manufacturing workflow. Selecting an unsuitable CAD tool can lead to three significant issues:

- Increased design time for complex boards

- Difficulty achieving error-free designs, especially for high-speed or RF boards

- Challenges in meeting electrical performance standards for intricate designs

Stay focused on the basics when evaluating design tools. Key questions to consider:

- Is it easy to learn?

- Does it have a user-friendly interface?

- Does it offer features tailored to your design needs?

- Does it include parts libraries or supports custom parts databases?

- Can it generate Gerber files compatible with most manufacturers?

- Does it automate design rule checks?

- Can it produce intelligent file formats like IPC or ODB++?

Qualifying PCB suppliers for first-attempt success

The major categories identified as the key factors for manufacturer selection:

- Raw materials used for laminates

- Machine capabilities

- Finishes for solder masks (e.g., glossy or matte)

- Delivery schedule flexibility

- Support for controlled impedance

- Types of via filling

- Solder mask colour and legend options

- Special profiling options (e.g., edge finger plating)

- Post-fabrication test methods

For high-density interconnect (HDI) designs

- Select vendors with proven HDI expertise to ensure high yield

- Review manufacturing capabilities early in the design process

- Confirm material availability to avoid delays; any later design change based on MFG review will cause additional timeline issues

- Address special requirements like stack-up selection and broadside impedance

PCB placement: Do’s and Don’ts

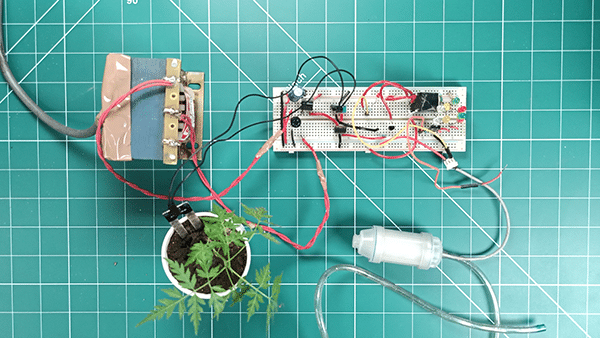

Component placement is where the art and science of PCB design converge. While no single approach works universally, orientation, placement, and layout heavily influence manufacturability.

Do’s

- Orient similar components to facilitate efficient and error-free assembly (manual+automated)

- Organise through-hole and surface-mount components to minimise assembly steps

- Ensure power, ground, and signal traces have clear paths

- Avoid components prone to heating issues during operation

- Place decoupling capacitors near their respective pins; use the schematic to drive this placement strategy

- Work one major component at a time, surrounding it by its related small parts

- Develop a placement strategy using a floor diagram before starting

- Adhere to mechanical constraints, such as height and keep-out zones

- Try to keep all parts on one side of the board. But if you must place parts on both sides, keep bottom side surface mount parts away from through-hole pins (This will make two-sided assembly possible, if not particularly cost-effective)

- Don’t break the rules or violate the DFx requirement of your supplier. Try to follow standards like IPC recommendation fairly

Don’ts

Here are some tips or no-good items that will help you get started:

- Avoid placing components on the solder side behind through-hole components

- Do not over-rely on auto-routing tools

- Become familiar with design for assembly (DFA) and guidelines provided by supplier, but do not assume the DFA guidelines are static—adapt as needed

- Familiarise yourself with component types, tolerances, and requirements that are unique to placement of PCBs.

- Use a routing grid that supports trace/space rules for consistent patterns

Most importantly, don’t hesitate to ask for help from your manufacturer’s CAM department or customer service. Seek early input from your manufacturer’s CAM department to minimise iterations.

Mastering PCB design is an iterative process requiring technical proficiency, collaboration with reliable manufacturing partners, and an unwavering commitment to precision. By implementing these strategies, designers can consistently produce innovative, manufacturable designs that meet performance and cost objectives.

The author, Ronak Desai, works at Infineon as the System Hardware Application Director. With over 22 years of experience in the Embedded Industry, he specialises in the design and development of embedded products and set-top box applications. His expertise encompasses microprocessor/microcontroller/RF and Wi-Fi-based products

The author, santhosh rangasamy, works at Infineon. He has over 15 years of experience in PCB layout designing and package design, PCB 3D layout simulation, DFM, DFA & DFT for PCB

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)