Check out our latest products

Researchers in Tokyo develops a hydrogen sensor capable of ultra-low concentration detection, initiating safer hydrogen energy systems.

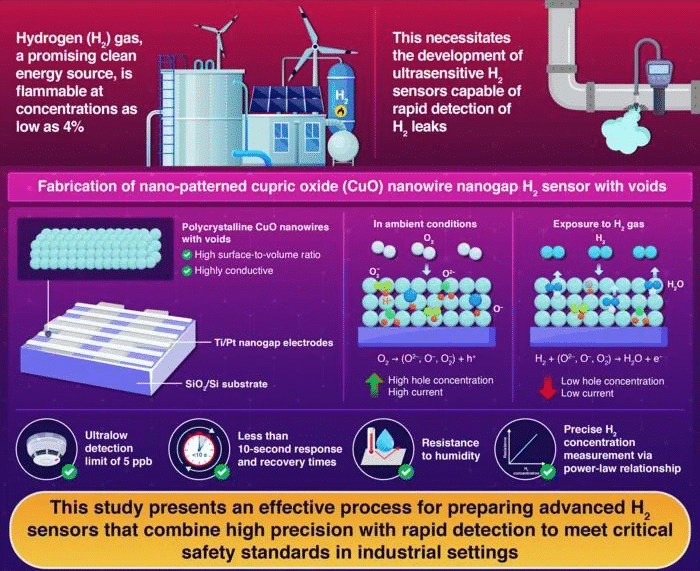

Hydrogen is widely regarded as a key player in the shift towards clean energy due to its ability to produce only water as a byproduct during combustion. However, its flammability and undetectable properties create significant safety risks. Addressing this challenge, a research team led by professor Yutaka Majima, institute of science, Tokyo has developed a unique hydrogen sensor capable of detecting concentrations as low as five parts per billion (ppb) with remarkable speed.

The sensor relies on nano-patterned copper oxide (CuO) nanowires mounted on a silicon substrate, with titanium and platinum electrodes. According to the researchers, the CuO nanowires exhibit high sensitivity, detecting changes in electrical resistance caused by hydrogen’s interaction with oxygen ions on their surface. These interactions form water molecules and reduce the concentration of positive charge carriers, leading to a measurable resistance increase.

This advanced sensor holds immense potential for industries handling hydrogen, including energy production, chemical manufacturing, and transportation sectors. Its ability to detect leaks promptly makes it vital for facilities prioritising safety and efficiency in hazardous environments. “We employed electron-beam lithography and two-step ex-situ oxidation to develop a reliable and reproducible process for preparing high-performance nano-patterned CuO nanowire-nanogap hydrogen gas sensors with voids, which is considerably different from conventional free-standing single-crystal CuO nanowires directly grown from copper sources,” said prof. Majima.

A pre-annealing process in a hydrogen-rich atmosphere, followed by oxidation in dry air, enhanced the sensor’s performance. This process reshaped the nanowires, increasing their surface area and structural integrity, which improved sensitivity. Furthermore, reducing the nanogap between electrodes to 33 nanometres amplified the electric field, enabling rapid detection within seven seconds and recovery in just 10 seconds.

The sensor also demonstrated resilience to humidity, a common limitation of hydrogen sensors while maintaining exceptional precision and speed. Its ability to detect hydrogen at both ultra-low and high concentrations underlines its potential for addressing industrial safety standards.

Prof. Majima concluded, “We will continue developing a wider range of gas sensors with this process to fabricate sensors for other hazardous gases as well.”

This innovation supports the safe adoption of hydrogen energy, aligning with global efforts toward sustainable energy solutions.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)