Check out our latest products

A Japan based company has introduced the world’s highest density laser diode module, advancing laser fusion technology.

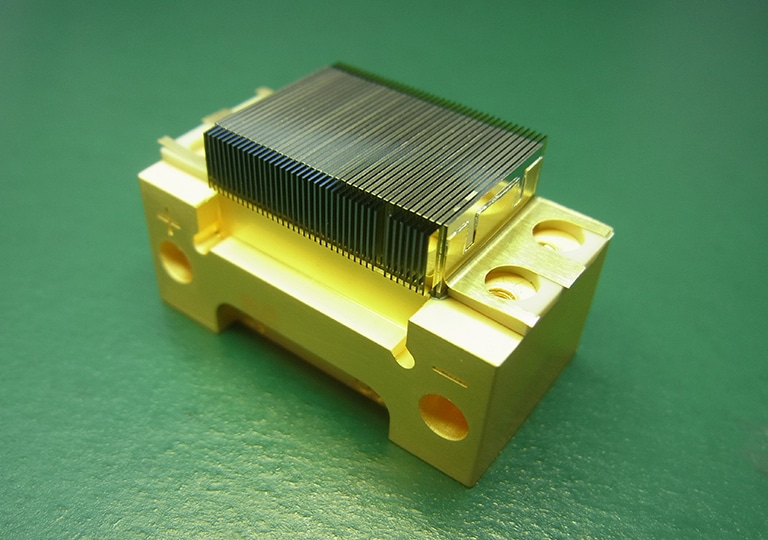

Hamamatsu Photonics, Japan has developed an innovative laser diode (LD) module with an unprecedented power density of 23kW/cm². This advancement is four times more powerful than their previous models and represents the highest level of LD modules for laser fusion research. The new LD module will serve as a light source for pumping lasers in fusion experiments, crucial for achieving 1kJ class power in laser fusion systems. This milestone is a significant step forward in the quest for practical laser fusion, which could pave the way for sustainable energy generation.

This breakthrough is not just limited to the field of fusion research but has broader applications for industries working on high power lasers. Target audiences include research institutions, universities, and laboratories focused on nuclear fusion, energy production, and space exploration. Additionally, sectors such as semiconductor manufacturing and space debris removal, which rely on high-powered lasers for precise operations, will benefit from the LD module’s advancements.

By improving manufacturing precision, the company’s proprietary technology enhances LD module efficiency and compactness, enabling high output laser systems to become more energy efficient and smaller in size. Nuclear fusion holds great promise as a carbon-neutral energy source. In laser fusion, lasers are used to irradiate a fuel capsule containing deuterium and tritium, triggering a fusion reaction. While major research facilities around the world are progressing with large scale experiments, the ability to achieve high repetition rates in laser fusion remains a challenge. The LD modules developed by Hamamatsu aim to address this by enabling lasers to operate at higher repetition rates, crucial for continuous energy generation.

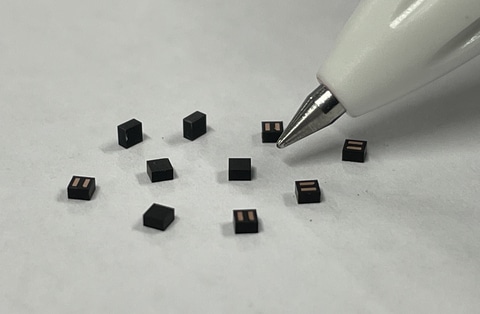

This breakthrough was achieved through the development of a high-density mounting technology for LD bars. Special jigs, improved solder joining techniques, and better heat sink structures have minimised leakage current and high cooling efficiency, making the new module the most powerful of its kind for laser fusion applications.

The company plans to commercialise this technology within the next three years, contributing significantly to future laser fusion power generation efforts.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)