Check out our latest products

A simple but powerful method to enhance the performance of eco-friendly kesterite solar cells, bringing them one step closer to competing with traditional silicon technology.

Over the past few decades, solar energy has become a major global player, powering homes and businesses worldwide. As demand grows, researchers have been searching for alternative materials that are sustainable, non-toxic, and cost-effective. Among the most promising candidates are kesterite-based materials like Cu₂ZnSnS₄ (CZTS), known for their affordability and eco-friendliness compared to conventional silicon photovoltaics.

However, kesterite solar cells have historically struggled with lower power conversion efficiencies (PCEs), primarily due to atomic-scale defects that trap charge carriers and cause non-radiative recombination—leading to significant energy losses.

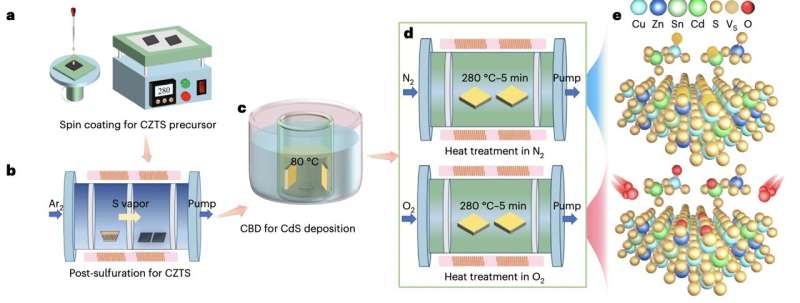

Now, researchers from Shenzhen University and the University of Rennes have introduced a passivation technique to tackle this issue. Their method involves heat-treating the CdS/CZTS heterojunction—the interface between CZTS and a cadmium sulfide buffer layer—in an oxygen-rich environment. This process allows oxygen atoms to occupy sulfur vacancies (VS), suppressing defects and reducing charge recombination.

“In this process, VS are occupied by oxygen atoms, suppressing VS defects,” wrote Tong Wu, Shuo Chen, and their team. They further explained that oxygen treatment also promotes the diffusion of cadmium ions into the absorber layer and forms beneficial Na–O and Sn–O complexes, leading to favorable band alignment and improved device performance.

When tested on real-world CZTS solar cells, the new technique achieved a certified efficiency of 11.51%—a notable milestone without requiring any additional additives or extrinsic doping. “We demonstrate a certified efficiency of 11.51% for air-solution-processed CZTS solar cells without any extrinsic cation alloying,” the researchers reported.

This could accelerate the real-world deployment of kesterite-based photovoltaics, making them a more competitive and sustainable alternative to silicon. Future refinements of the method could increase efficiencies, opening new doors for greener and more flexible solar technologies.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)