Check out our latest products

A new cloud-based tool transforms inductive coil design with real-time simulations, reducing costs and material waste.

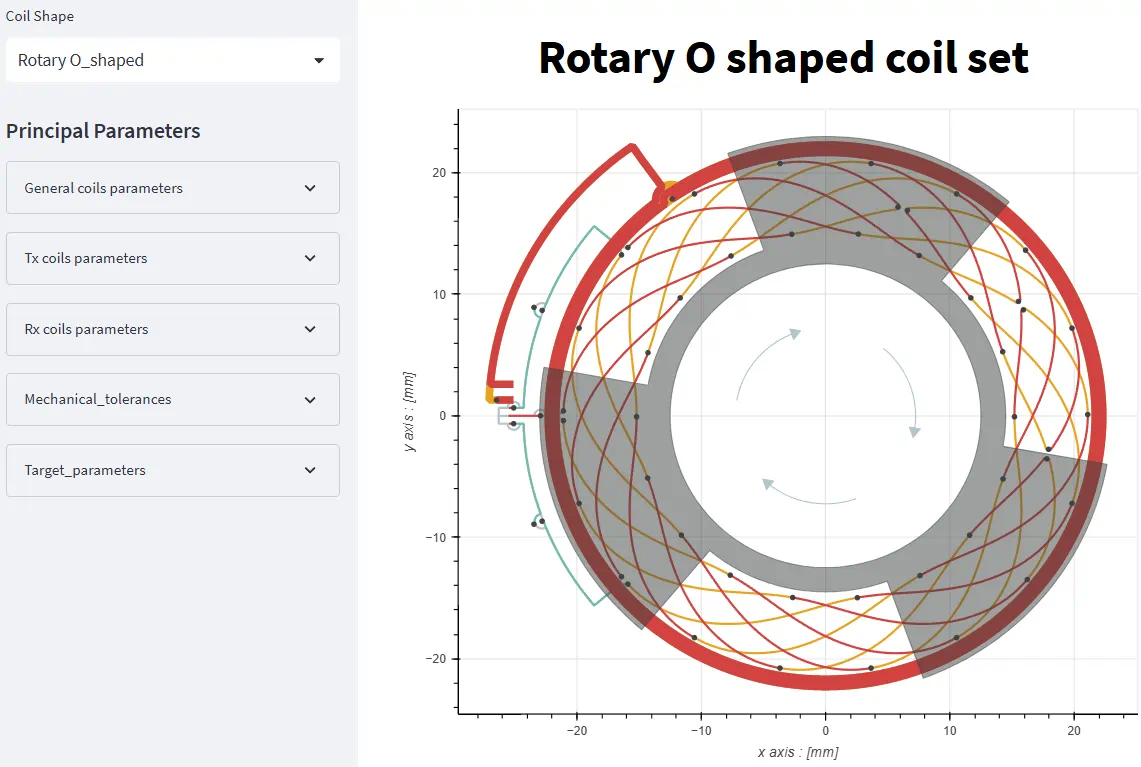

A unique web tool for inductive coil design and simulation has been developed by Melexis, Belgium. This innovation allows engineers to create, visualise, and optimise coil layouts in real time, promising to transform the design process for industrial and automotive sensors.

The platform employs a user-friendly graphical interface that simplifies the creation of various coil shapes, including rotary “C” and “O” designs, and configurations for linear and arc applications. Designed for engineers working on industrial and automotive sensor systems, the tool caters to both experienced professionals and those with minimal prior knowledge of coil design. Its digital approach eliminates reliance on physical prototypes, significantly cutting development time and minimising material waste.

“This tool has been created to capture Melexis’ extensive inductive simulation knowledge and make it readily available to engineers worldwide, completely free of charge,” stated Lorenzo Lugani, product line director, Melexis.

Engineers using the tool can simulate the interaction of their designs with Melexis inductive sensor ICs, such as the MLX90510, MLX90513, and MLX90517. The virtual platform offers real-time configuration updates, allowing users to assess sensor performance instantly. The system also produces optimised Gerber files for manufacturing and delivers detailed reports addressing potential errors, from assembly tolerances to lifetime variances.

Tailored to the company’s patented 3-phase coil design, the tool supports multiple sensor topologies, including through-shaft, side-of-shaft, and end-of-shaft setups, and accommodates both two- and four-layer PCB designs. Professionals designing motor position sensors, pedals, actuators, or steering systems will find the tool particularly useful for integrating highly reliable and accurate sensing ICs into their projects.

The tool has been well-received during its trial phase, with testers applauding its ability to streamline the R&D process for engineers across varying levels of expertise. “By moving the R&D process into the virtual domain, engineers can redefine their development process for inductive sensors, leading to significant reductions in costs, efforts, and material wastage,” Lugani added.

Its availability marks a significant step forward in leveraging digital tools for advanced sensor technology, offering practical solutions for the evolving needs of industries worldwide.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)