Check out our latest products

This method can potentially reshape sustainability in robotics, electronics, and beyond, setting a new standard for circular innovation.

Over the past decades, robotics has evolved remarkably, driven by advancements in electronics, mechanics, and software. However, rapid innovation often renders older robots obsolete, contributing to significant electronic waste. Addressing this issue, researchers at the Singapore University of Technology and Design (SUTD) have unveiled a revolutionary approach for upgrading soft robots, potentially transforming sustainability in robotics. Their findings introduce a three-dimensional (3D) printing process using a specially formulated gel.

Sustainability, often overlooked in robotics, became the cornerstone of SUTD’s research. The team’s method not only extends the lifespan of soft robots but also offers compatibility with consumer products, opening doors to broader applications.

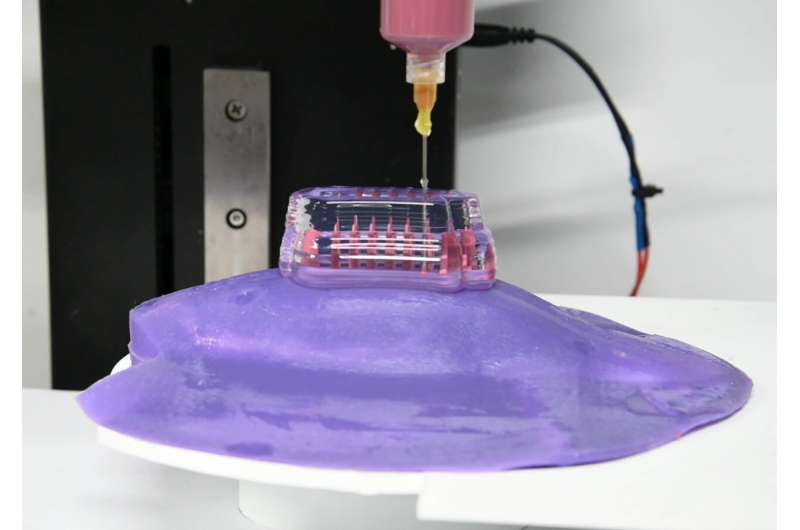

Central to their innovation is an in-situ additive manufacturing process that enables precise upgrades and repairs. First, a gel support is printed onto the robot’s surface, tailored to hold its shape without additional containers. Multi-material components are then printed directly onto the gel-covered areas, ensuring stable curing. Once complete, the gel is easily washed away, leaving seamlessly integrated new features.

The team demonstrated this approach by upgrading a batoid-inspired soft robot with tactile sensors, whiskers, and actuated hooks. They also repaired synthetic skin damaged during testing. The versatile gel is compatible with various surfaces, making the method adaptable across diverse robotics applications and electronic devices like smartphones and smart appliances. The broad material compatibility and ability to extend the life of soft robots are key advantages, they aim to develop more sustainable fabrication techniques that promote material circularity across industries.

“We’ve been focusing on multi-material additive manufacturing for years,” shared Pablo Valdivia y Alvarado, senior author of the paper. Soft robots, unlike traditional ones, are particularly challenging to repair. Many prototypes are discarded when new functionalities emerge or severe damage occurs, creating substantial waste.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)