Check out our latest products

Collaboration between Murata Manufacturing and Japan’s NIMS has produced a massive AI-ready materials database that could revolutionize electronics and energy storage development.

In a major breakthrough for materials science and electronic innovation, Murata Manufacturing Co., Ltd. and the National Institute for Materials Science (NIMS) have unveiled the largest-ever database of dielectric material properties. The research leverages over 20,000 samples extracted from more than 5,000 academic papers, offering a goldmine of information for AI-driven materials discovery.

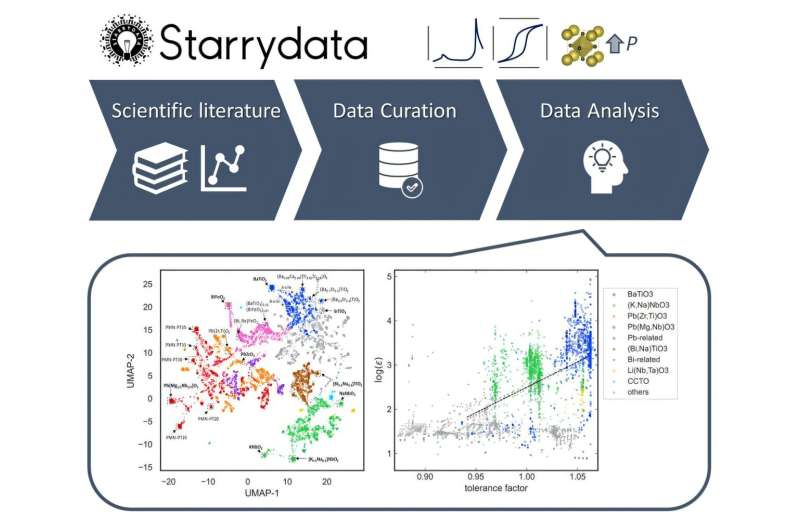

The data compilation was made possible through the Starrydata2 web system, which allowed researchers to collect experimental values from scientific literature systematically. Crucially, the NIMS team developed a standardized method to extract temperature-dependent properties from scientific graphs—data often missing in existing repositories.

“What sets our work apart is the rigorous manual process we applied to ensure the data was clean and consistent,” said the researchers. This meticulous approach enables more accurate machine learning (ML) models to predict the behavior of new materials, particularly for electronics and energy storage applications.

Initially functioning as black boxes, the ML models were further enhanced through visual data mapping and clustering algorithms. This allowed researchers to not only predict properties but also understand the why behind them. The team identified patterns that link chemical composition with electronic performance by grouping similar materials.

Among the highlights of the analysis was a deep dive into ABO₃ perovskites—key components in devices like smartphones, solar panels, and batteries. The team confirmed a clear correlation between these materials’ structural features and dielectric permittivity, aligning with long-standing scientific theory.

This comprehensive effort shifts the paradigm from trial-and-error to data-driven material innovation. “By creating the most extensive dataset and applying sophisticated ML techniques, we’ve visualised the entire dielectric material space like never before,” the team noted.

Looking ahead, NIMS plans to release the database publicly in 2026, with future expansions possibly including manufacturing parameters. This could enable predictions that bridge design with real-world fabrication processes, potentially accelerating the development of next-gen electronic materials.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)