Check out our latest products

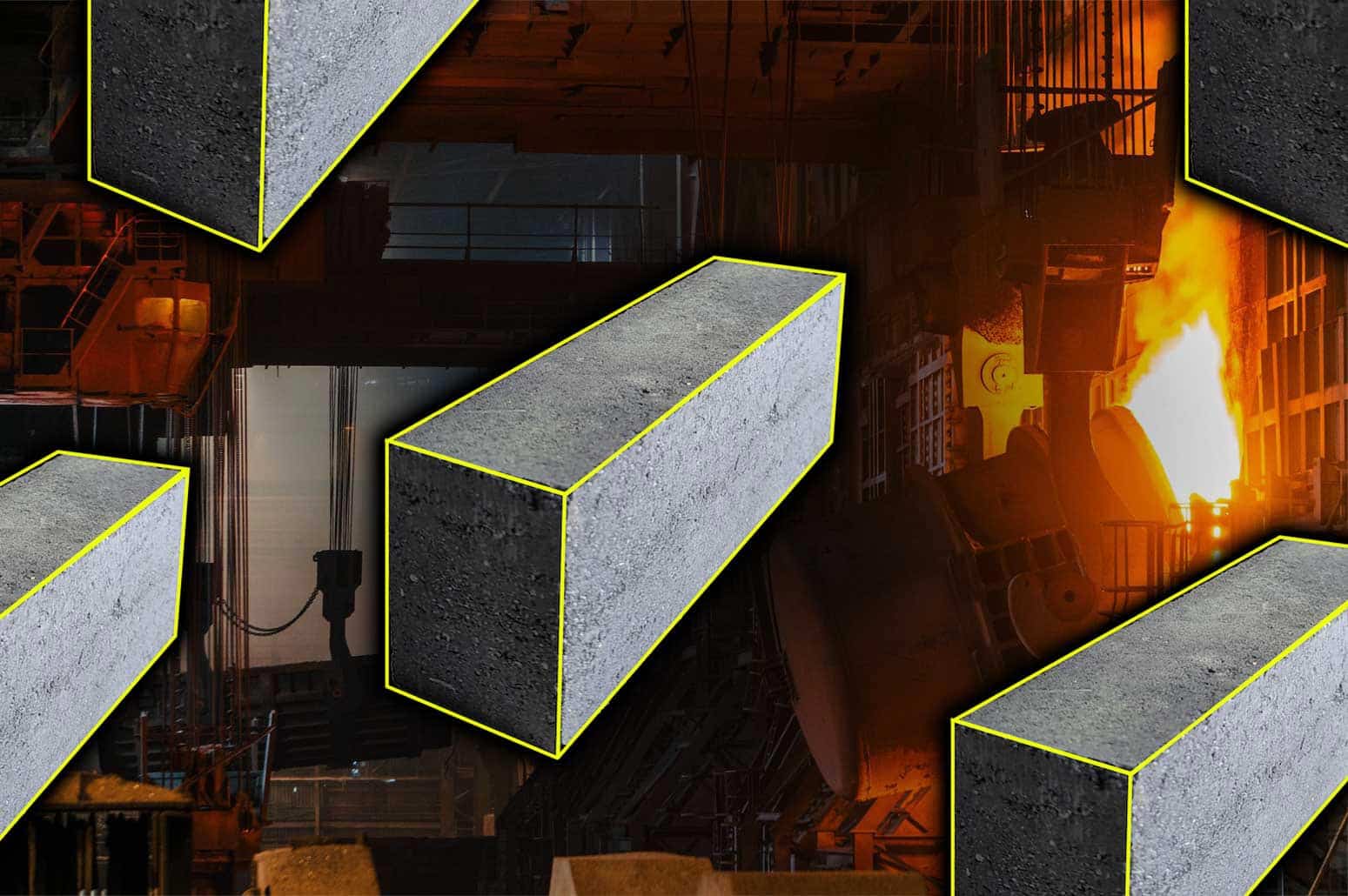

MIT researchers develop a technique in electric heating to decarbonise heavy industries using firebrick-based thermal batteries.

Electrified Thermal Solutions, an MIT spinout, has developed electrically conductive firebricks capable of storing and delivering heat at temperatures exceeding 3,000°F. This innovation, engineered by MIT alumnus Daniel Stack, promises to decarbonise energy-intensive industries such as steel, cement, and chemicals by utilising renewable electricity for heat production.

These firebricks, created from modified ceramic materials, store heat efficiently and release it for industrial use. They tap into cheap, clean electricity during off-peak hours, providing a cost-effective alternative to fossil fuels. “The idea was to skip electric heaters and let firebricks produce heat directly,” said Stack, emphasising the simplicity and scalability of the solution.

Industries requiring high-temperature processes, including manufacturers of steel, glass, paper, and specialty chemicals, stand to benefit significantly from this breakthrough. These sectors often face challenges in transitioning to clean energy due to their reliance on fossil fuels for heat. Electrified Thermal’s technology offers them a practical pathway to decarbonisation without compromising operational efficiency.

The U.S. industrial sector, a significant carbon emitter, heavily relies on fossil fuels for high-temperature processes. Electrified Thermal’s breakthrough allows industries to replace traditional heat sources with zero-carbon options, addressing a long-standing barrier to sustainability.

This technology leverages electricity from renewable sources like wind and solar, particularly during times of low demand when electricity prices drop significantly. Stack noted, “In many U.S. regions, electricity prices turn negative for over 20% of the year. Our solution harnesses this opportunity while cutting costs and emissions.”

Stack’s journey began in 2014 at MIT, where his research shifted from nuclear reactors to thermal storage. By tweaking the chemical composition of traditional firebricks, he and his advisor, Charles Forsberg, developed the conductive firebrick technology now central to Electrified Thermal’s mission.

The company has successfully demonstrated its system, storing up to 25 megawatt-hours of energy. Their firebricks, manufactured using standard processes, enable rapid scalability and compatibility with existing supply chains. “From the start, we designed these e-bricks to integrate seamlessly into industrial operations,” Stack added.

With a megawatt-scale system slated for operation within months, Electrified Thermal aims to showcase its commercial viability. “Next year will mark a major turning point,” Stack predicted, signalling hope for a cleaner, more sustainable industrial future.

This development holds the potential to transform global heavy industries, making zero-carbon heating affordable and practical at scale.

![[5G & 2.4G] Indoor/Outdoor Security Camera for Home, Baby/Elder/Dog/Pet Camera with Phone App, Wi-Fi Camera w/Spotlight, Color Night Vision, 2-Way Audio, 24/7, SD/Cloud Storage, Work w/Alexa, 2Pack](https://m.media-amazon.com/images/I/71gzKbvCrrL._AC_SL1500_.jpg)

![[3 Pack] Sport Bands Compatible with Fitbit Charge 5 Bands Women Men, Adjustable Soft Silicone Charge 5 Wristband Strap for Fitbit Charge 5, Large](https://m.media-amazon.com/images/I/61Tqj4Sz2rL._AC_SL1500_.jpg)